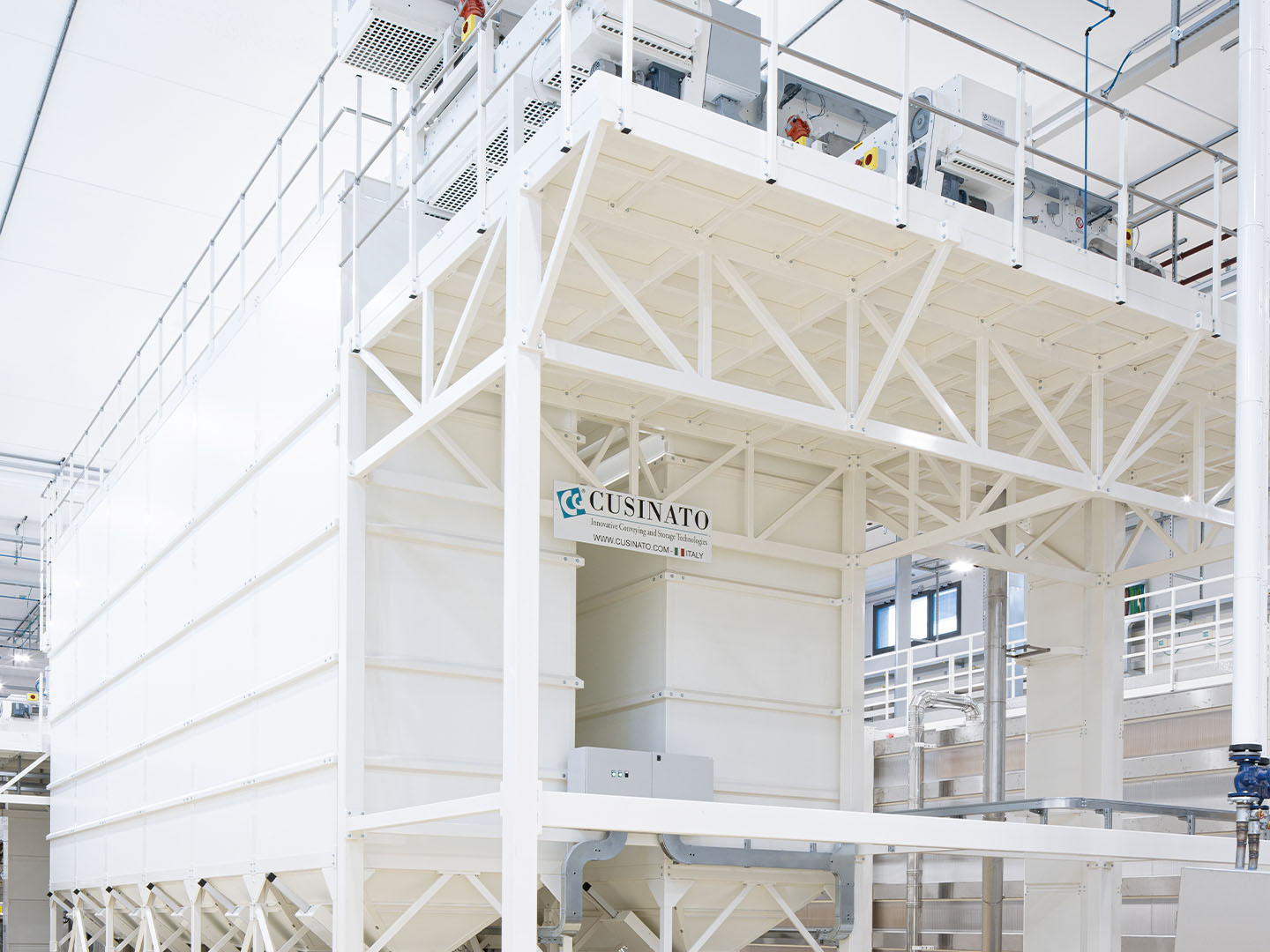

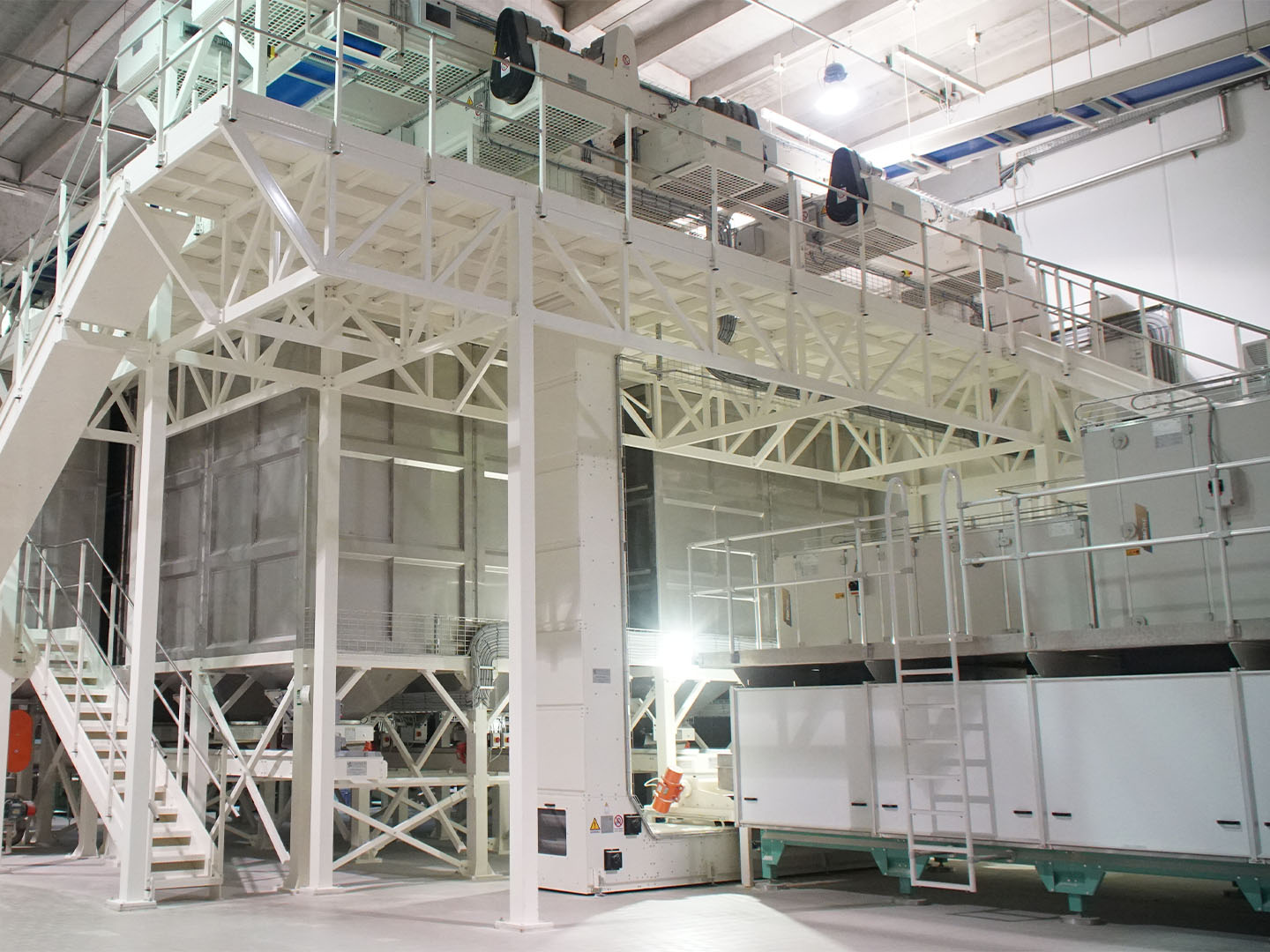

Industrial storage systems

Storage and handling systems tailored to each customer’s needs, with a strong focus on hygiene and reliability

Cusinato industrial storage and handling systems are a complex system for conveying and storing fragile products, both granular and non granular. These systems are designed to distribute products from production lines to silage systems and, subsequently, to packaging lines.

Our industrial storage and systems, which generally comprise a series of machines connected to each other, mainly perform functions such as storing, extracting and handling, conveying and cleaning products through systems consisting of:

- Elevators (of various models, including the patented Kappa series)

- Silos

- Conveyor belts

- Feeders and Extractors

- Vibrosieves

and many other machines, depending on processing requirements.

Cusinato specialises in highly customised industrial storage systems serving all production and packaging lines, which allow for maximum flexibility of use. As a result, any production line can be connected to any packaging machine at the same time.

Special attention is paid to each project to make sure that as much storage volume as possible is obtained in the available space. Cusinato designs and installs storage systems that are also suitable for challenging spaces since they can be adapted to irregular spaces and pre-existing systems, while always making sure that production can continue to avoid downtime.

Cusinato storage systems are carefully designed down to the smallest detail to prevent dust and product fragments from depositing and product contamination as much as possible when changing production batches.

During R&D and Design phases, we focus on ensuring that our systems are highly reliable and on reducing the need for maintenance, which is close to zero.

Strengths of Cusinato industrial storage systems for the food and non-food industry:

- Experience in managing operating sequences, which allows product flows to be optimised, maximising plant productivity;

- Work cycles according to recipes, maximising efficiency and cutting down production costs;

- Easy product traceability;

- Maximum reliability of the machines over time, even in “difficult” working environments;

- Ability to ensilage and store complex products, such as “capelli d’angelo” pasta and pasta nests, or particularly fragile products, or in general, that are difficult to handle;

- Optimisation of available space.

STORAGE EVOLUTION 8.0

Each Cusinato storage and handling system is equipped with a powerful and flexible monitoring application, the STORAGE EVOLUTION 8.0. The program, which is SCADA / HMI-based, has been optimised so that storage phases can be set up quickly and safely, for improved production process performance.

Features:

- Operation tailored to specific storage needs;

- Interfaceable with the most popular MES, ERP and Industry 4.0 systems;

- Records system operation and traces the product’s route;

- Remote assistance support, also through innovative Cusinato systems;

- Integrates customisable system maintenance programmes, spare parts request and intervention ticketing.

Strengths:

- Intuitive operation and ease of use;

- Simultaneous viewing of all ongoing activities;

- Work sequence programming;

- Management of product mixtures (e.g. “multi-coloured pasta”) with synchronisation of the quantities of each component in various modes, as required by production management;

- Traceability by product code, with recording of routes, times and quantities supplied.