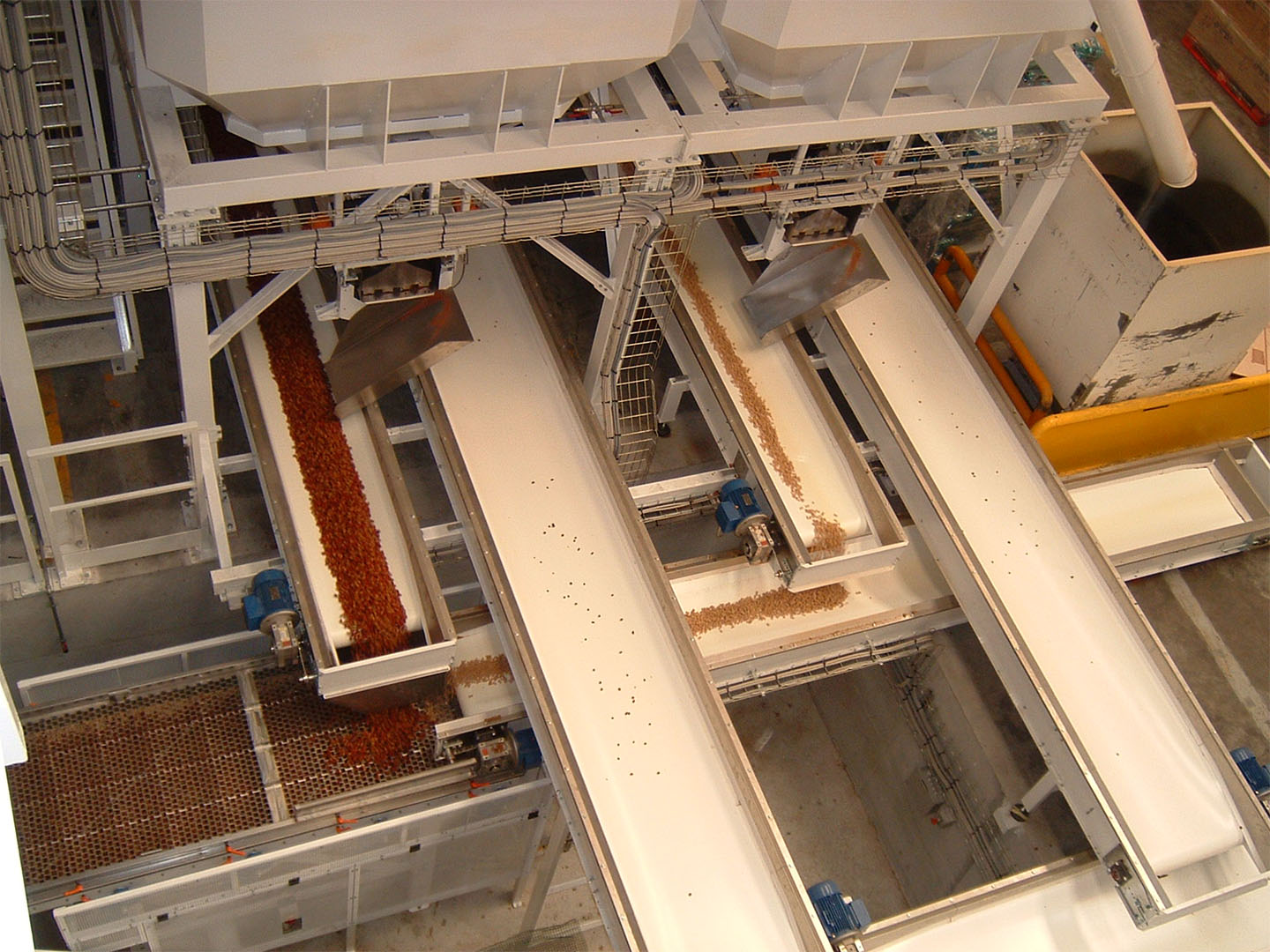

Industrial Pet Food Storage Systems

Pet Food Storage systems with a focus on functionality and flexibility.

Cusinato Pet food storage systems are designed to conveying and storing dry food for dogs and cats, designed to distribute products from production lines to silage systems and, subsequently, to packaging lines.

The systems, structured in series of iron or steel silos, are used as an intermediate storage place between the production and packaging phases, and can carry out functions such as mixing to obtain multi-flavoured pet food (made up of different kinds of dry food, in different proportions).

Pet food storage systems can comprise the following machines:

- Elevators

- Silos and buffers

- Redler belt conveyors

- Feeders and Extractors

- Vibrosieves

Cusinato’s pet food storage systems make the best use of the available space to achieve as much storage volume as possible in the smallest amount of space. They are carefully designed down to the smallest detail to prevent dust and product fragments from depositing and contamination when changing production batch.

Strengths of Cusinato’s pet food storage systems:

- Intuitive operation and ease of use;

- Easy product traceability;

- Maximum reliability of the machines over time, even in “difficult” working environments;

- Ensilage and storage of complex, oily or fragile products or products that do not flow easily;

- High range of product flow rates, particularly for cleaning and sifting systems;

- Maximum loading and unloading flexibility, for complete dies fed to the packaging machines (“from each line to each packaging machine”).

STORAGE EVOLUTION 8.0

Each Cusinato system is equipped with a powerful and flexible monitoring application, the STORAGE EVOLUTION 8.0.

The program, which is SCADA / HMI-based, has been optimised so that storage phases can be set up quickly and safely, for improved production process performance.

Main features:

- Operation tailored to specific storage needs;

- Interfaceable with the most popular MES, ERP and Industry 4.0 systems;

- Records system operation and traces the product’s route;

- Remote assistance support, also through innovative Cusinato systems;

- Integrates customisable system maintenance programmes, spare parts request and intervention ticketing.

Strengths:

- Intuitive operation and ease of use;

- Simultaneous viewing of all ongoing activities;

- Work sequence programming;

- Management of product mixtures with synchronisation of the quantities of each component in various modes, as required by production management.

- Traceability by product code, with recording of routes, times and quantities supplied.