Bucket Elevators – The “Patented” K Series

Conveying fragile products while preserving their integrity is what we specialise in.

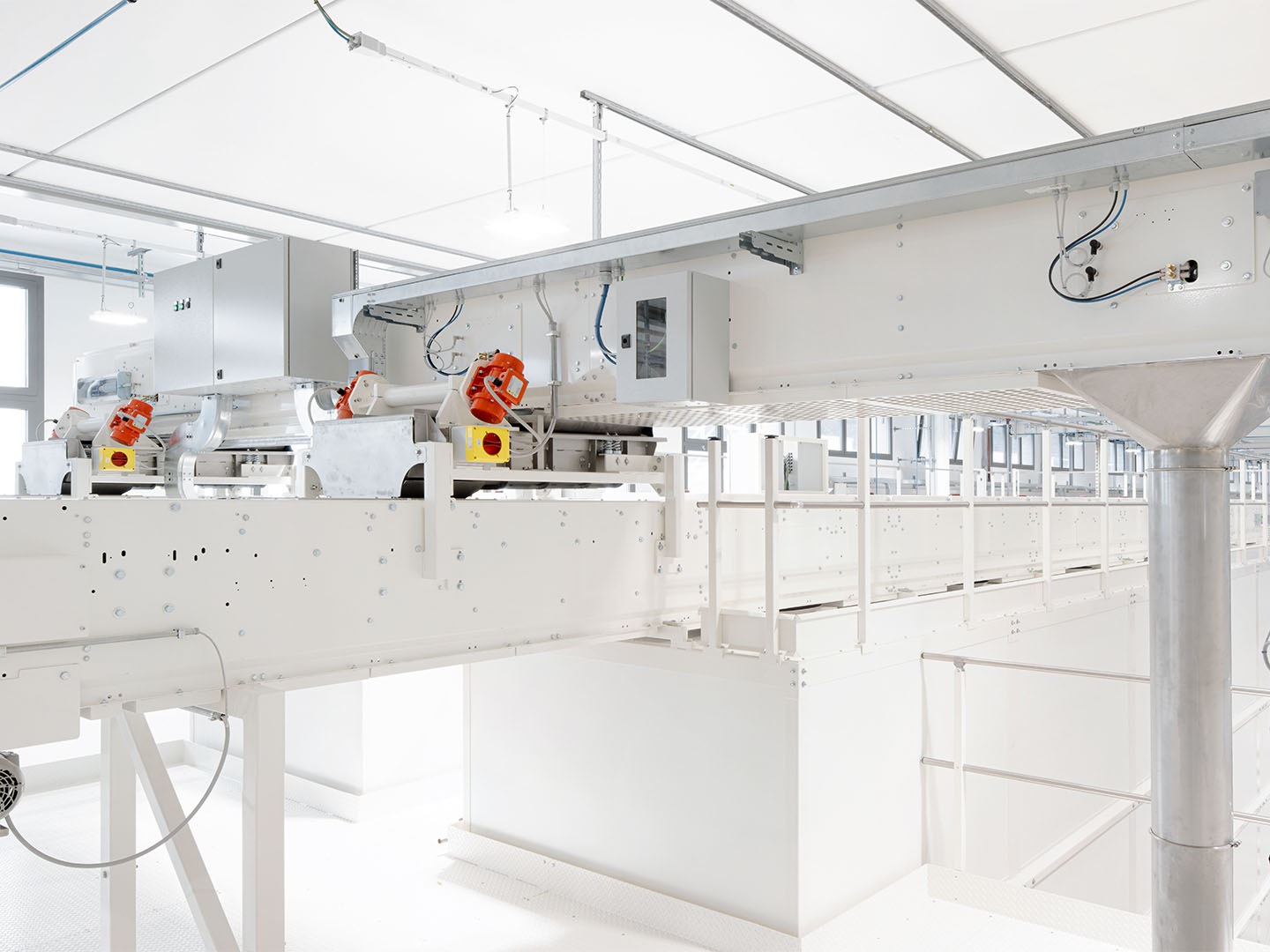

The Cusinato bucket elevators and bucket conveyors are machines designed to convey fragile granular products such as dry short pasta, couscous, pet food, legumes, dried fruit and nuts, sweets, frozen food, and much more. Our bucket elevator conveyors are of high quality, flexible and customisable. They are available for both vertical conveying (bucket elevators) and horizontal conveying (bucket conveyors). Cusinato’s is patented solution to convey products in food and non-food industries ensures that all types of product conveyed remain intact and leakproof.

The Cusinato patent is what makes this bucket elevator model an innovative, high-performance machine: for example, thanks to the option of setting various special configurations, such as “Z”, “O” or even “F” or “T”, and any other shape that is necessary to reach areas that are difficult to reach for other elevator models.

Strengths of the K series bucket elevators:

- Perfect seal between buckets during loading without oscillations (Cusinato patent);

- Endless configurations in the elevator structure;

- 360° bucket rotation to ensure complete emptying;

- Wide range of bucket capacities made of innovative materials: metal (iron or stainless steel), metal detectable plastic (suitable for contact with food in accordance with applicable regulations in the food industry), wire mesh and many others;

- Buckets with customised features depending on the type of product to be conveyed;

- Special anti-drip profiles to avoid contamination from chain lubricant;

- Support and guide system of the chain in a self-lubricating material, assembled on exclusive extruded anodised aluminium profiles to increase rigidity and resistance over time;

- Extremely hygienic system to avoid stagnation and cross-contamination between products when changing production batches;

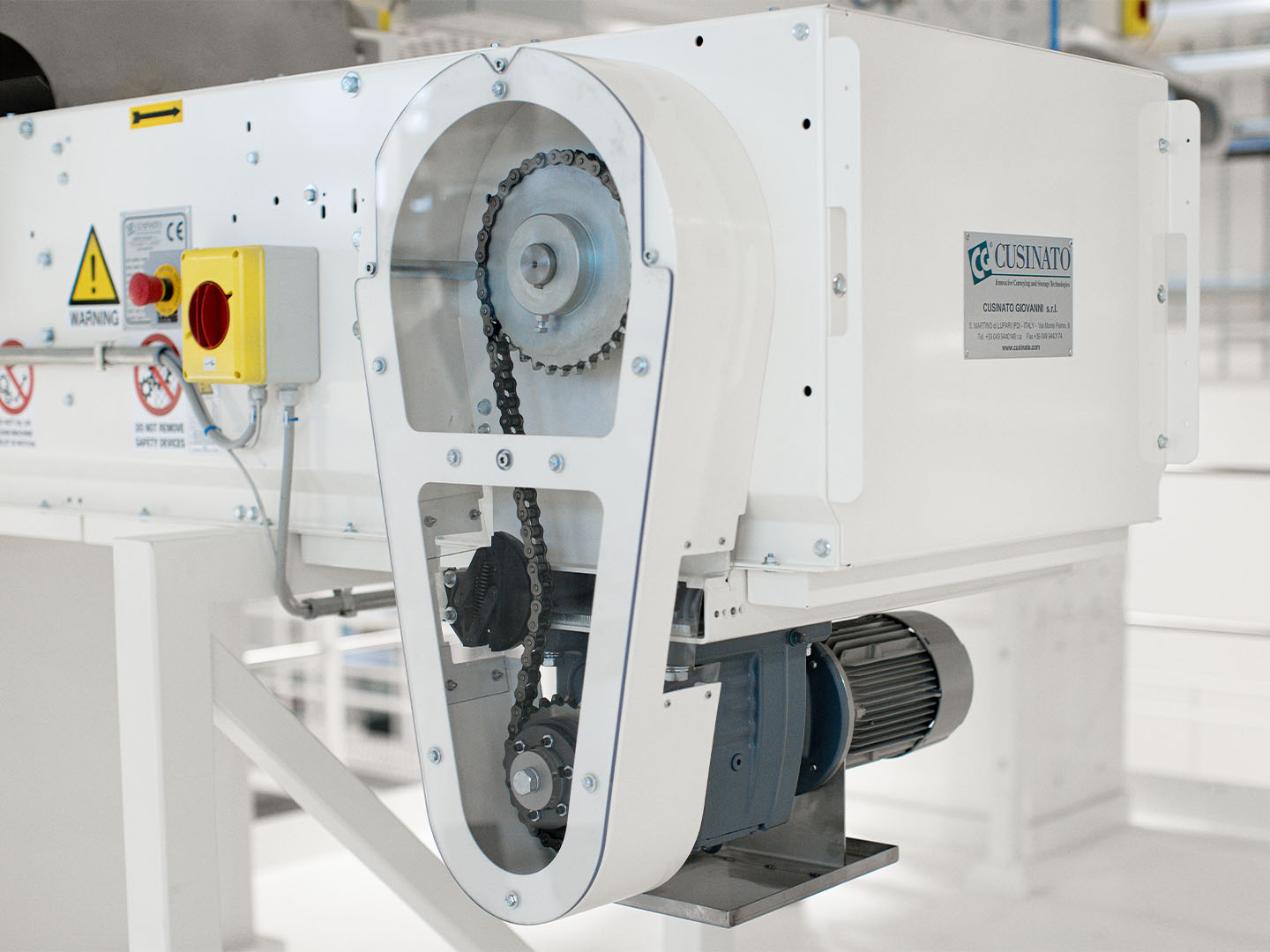

- High-quality, sturdy mechanical design to ensure minimal maintenance and a long life;

- System complete with active and passive safety devices to prevent mechanical breakage;

- Option of an automatic chain lubrication system, programmable and customisable via PLC, especially appreciated by those who work in dusty environments.

LOADING-UNLOADING POINTS

Each bucket elevator has one or more loading points with perfect sealing at any point of the horizontal section. Unloading can be single (fixed unloading) or multiple (more than one electro-pneumatic unloading). During the unloading phase, the bucket is rotated by 360 degrees, for safe, reliable and complete unloading, with very low impact and mechanical wear.

SUPPORT AND GUIDE SYSTEM OF THE CHAIN

The special system used to support and guide the chain, with profiles made of a self-lubricating material with a very low coefficient of friction, is mounted on dedicated extruded anodised aluminium support profiles (exclusive Cusinato design) and ensures minimal maintenance and a very long life for both the chain and the guide.

In addition, thanks to special anti-drip shaped profiles present in all horizontal sections, it is possible to prevent lubricant from contaminating the chains. In recent versions, the bucket elevators are also available with several optional accessories, including the internal anti-stagnation profiles of the conveyed product.

BUCKETS

The buckets have patented devices (a Cusinato exclusive) to avoid product losses, which are made of innovative materials that are compatible with food products. They are available in different versions and sizes depending on the product to be conveyed and required conveying capacity. Since 2016, all plastic buckets have been produced in a metal detectable version in order to meet food safety requirements.

Moreover, the Cusinato bucket elevators can be equipped with an opening window with a turning unit so that the buckets can be easily cleaned.